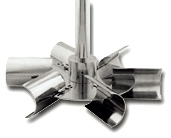

In aerobic fermentation, production from microbial growth and metabolism requires enough oxygen. To make full use of the oxygen in the aseptic air by the microbe in the fermentation, it is required to dispense the air. And in terms of how to make thorough gas dispersion, save electricity, the design and configuration of the mixing impeller are the key. The 1950s saw the emergence of six curved blade, flat blade structure used in microorganism fermentation mixing, which played a certain effect. But the blade has obvious flaws, the gas dispersing emulsification degree is low, in the situation of high fermentation liquid viscosity and large air volume, the mixing effect is not pleasing, and power consumption is unsatisfying. In order to meet the requirements of microorganism fermentation mixing, our company developed a HLG series of advanced energy-saving stirrer, with a wide application for amino acids, organic acids, enzymes, and antibiotic pharmaceutical fermentation, the effect is remarkable.

Technical Background

Features

HLG series energy-saving stirrer,based on different fermenter structure and fermented liquid media properties, adopt different impeller design, leading to the generation of both radial flow, and the axial flow with vertical agitation. Gas dispersion effect is good, and bubble stays for a longer time; gas-liquid mass transfer coefficient increase as well as the dissolved oxygen, and power consumption decrease, leading to a fermentation yield. Through actual production application, HLG combination impeller, in the same fermentation conditions (medium, rotational speed and impeller diameter, number of impeller, ventilation ratio and tank pressure, etc.), has the following features compared with the traditional mixing impeller:

Mass transfer coefficient increased by 50%; gas dispersed to improve the bubble emulsifying capacity by 40% - 50%; uniform distribution of dissolved oxygen in the fermentation tank, and can shorten the mixing time(including media, anti-foaming agent, etc.), which is advantageous to a high product yield

Fermentation power consumption decreased, the stirring power dropped by 10% - 30%. In heavy-duty fermentation production, unit drop of comprehensive energy consumption is even more significant, so the overall economic benefit is remarkable.

HLG-4