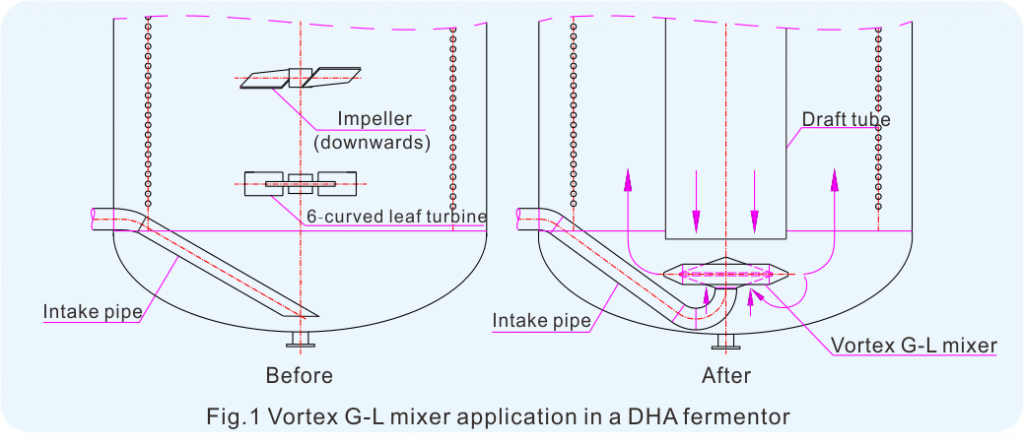

This company originally adopted a straight through intake in a 45m3 DHA fermentor, as shown in Fig.1. And it was equipped with mechanical agitation: 4-leaf impellers in three levels of the upper region, and 6-curved leaf turbine at the bottom, motor power is 55kw.

Existing problem

Straight through intake pipe had a bad gas-liquid mixing result. Huge bubbles and unstable liquid level could be observed, which indicated that oxygen was not well utilized. The mixing system has some defects and was prone to contamination.

Implementation of fermentor modification

Replace the original mixing system with vortex gas-liquid mixer. As shown in the right part of Fig. 6.

Fermentor modification results:

(1)No stirrer shaft current consumption; reduce electricity consumption by 100%, and eliminate contamination risk in mixing system.

(2)Stable liquid level, no huge bubbles.

(3)Product yields improve remarkably, stabilize production.

(4)No stirring heat and no noise, energy-saving and environmentally-friendly.

In this case, although draft tube is not installed due to the small size of fermentor, fermentation DO level has a good result. Much more satisfactory result will be obtained if draft tube is installed in the air lifting bio-reactor.